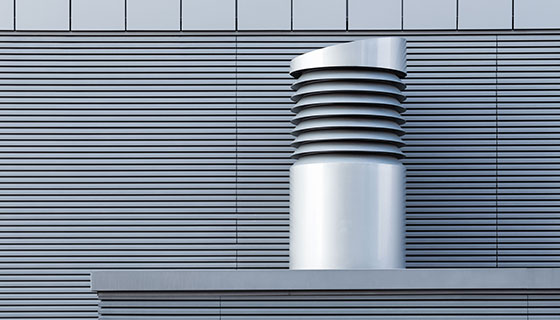

Pressurization Purification System

Pressurization Purification System (PPS) can be used for high concentrations of odors & corrosive contaminants and municipal & industrial air purification and it can also be used for the abatement of releases of toxic airborne contaminants, thus preventing them from infecting the space.

| DBS Series(Deep Bed Scrubber) |

DBS Series(Deep Bed Scrubber)

Introduction

Odor and corrosion problems from various manufacturing processes are often the result of multiple airborne contaminants. Industries such as pulp and paper, oil and gas refineries and wastewater treatment generate contaminants such as hydrogen sulphide, an undesirable by-product, which is malodorous, toxic and highly volatile. In wastewater treatment facilities, specific characteristics such as basin detention times, loadings to biological processes and sludge generation potential can influence the odor levels.

Septage and sludge handling systems are also common sources of strong odors. Odor generation is often the result of organic overloading, inadequate supply of air, improper ventilation, or simply the failure to recognize that certain unit processes may require the implementation of special odor control technology. Typical nuisance odors and corrosive contaminants are also produced in the manufacturing of chemicals, fertilizer, pharmaceuticals and food processing, as well as waste transfer stations, incineration plants and garbage depots.

The ability to control odorous emissions has become a growing concern as cities and populations are expanding closer to plant facilities. The objective of odor control is to prevent or minimize nuisance odor levels to the surrounding community. Safety and comfortness of the employees working in plant facilities has also become a top priority. National and local regulations on air quality are more severe, responding to neighbour complaints and environmental groups.

IIECC Deep Bed Scrubber(DBS) systems can be used for high concentrations of odors & corrosive contaminants and municipal & industrial air purification and it can also be used for the abatement of releases of toxic airborne contaminants, thus preventing them from infecting the space.

Traditional solutions used for odor and corrosion problems consist of two types of systems: wet scrubbers and dry scrubbers. Wet scrubbers are typically large towers utilizing chemical solutions to neutralize the odors. These types of systems are used in cases of very high concentrations (greater than 20 ppm) in order to reduce contaminant loads. Wet scrubbers require a major investment and substantial maintenance costs.

IIECC Deep Bed Scrubber (DBS) are smaller dry scrubbers filled with filtration media. Smaller concentrations (less than 20 ppm) require DBS to efficiently remove contaminants to non-detectable levels.

Servicing DBS is minimal, only requiring annual bulk loading of the replacement media rather than complex and frequent maintenance procedures necessary for wet scrubbers.

Features

-

VARIOUS MEDIA FOR CUSTOMIZED SOLUTIONS

Certain applications have several contaminants which are more complex to eliminate. Gas phase filtration often requires more than one type of filtration media in order to efficiently remove contaminants. IIECC Deep Bed Scrubber (DBS) is the ideal solution when multiple filtration media sections are required.

-

ENGINEERED VERSATILITY

IIECC's engineering and R & D departments have simplified the process of designing custom DBS systems allowing more versatility for the specifier and providing a superior quality/price ratio.

-

SIMPLIFIED MEDIA REPLACEMENT

The multiple media sections allow replacement of individual media beds. Maintenance no longer requires changing all the media but only the consumed portion, which can be determined through our media life analysis service. Bulk loading and unloading allows for considerably reduced downtime.

-

EASIER ACCESS AND REDUCED HEIGHT

IIECC DBS system offers easy access to the filters due to its horizontal design and full-sized doors. Unlike vertical scrubbers, the Deep Bed Scrubbers are suitable for limited height applications.

-

MATERIAL CONSTRUCTION VERSATILITY

IIECC Deep Bed Scrubbers are manufactured from either corrosion protected mild steel, aluminum, or stainless steel. Our wide material selection enables us to meet specific needs of the client at minimum cost.

Configurations

| Zinc coated steel protected by a three-coat corrosion resistant paint. | 30% efficiency (MERV 6) 2" pre-filter. | Up to three filtration media beds for odor and corrosion control. |

| 30% efficiency (MERV 6) 2” after-filter. | 90% efficiency (MERV 14) 12" final filter. | Backward inclined plug blower or single inlet centrifugal blower. |

| Perforated stainless steel 316 media section. | Bulk media filling port. | Bulk media discharge gate (optional vacuum port). |

| Full size hinged access doors. | High pressure stainless steel screw-on latches. | Structural C-channel base. |

| Insulated double-wall panel construction. |

Applications

| Pulp & paper | Digesters | Incineration plants |

| Oil & gas refineries | Exhaust pressurization | Garbage depots |

| Clarifiers | Wet wells | Process areas |

| Waste transfer stations | Emergency safe rooms |