Landfill Leachate Treatment

Landfill leachate is different from general urban sewage and is a high-concentration organic wastewater. It is characterized by high content of COD, BOD5 and NH3-N, oil content, complex water quality and great harm. IIECC adopts integrated or modular equipment, which has the advantages of small floor space, reduced civil construction, investment saving, good effluent quality, fully automatic control, simple operation and convenient maintenance and management. The core processes are Iron-Carbon microelectrolysis and Moving-Bed Biofilm Reactor (MBBR).

Fe/C Micro-electrolytic Material Treatment System |

A/O+MBBR Biochemical Treatment System |

Integrated Treatment Equipment |

Modular Treatment Equipment |

| Iron-Carbon microelectrolysis The iron-carbon microelectrolysis method is used to degrade most of the macromolecular organic pollutants contained in the wastewater into small molecular substances, and reduce COD, SS and chromaticity to provide conditions for subsequent biochemical treatment. Microelectrolysis technology is an ideal process for the treatment of high-concentration organic wastewater. Principle In the absence of electricity, the microelectrolytic material filled in the wastewater itself generates a potential difference of 1.2 V to electrolyze the wastewater to achieve the purpose of degrading organic pollutants. |

|

|

Products & Services

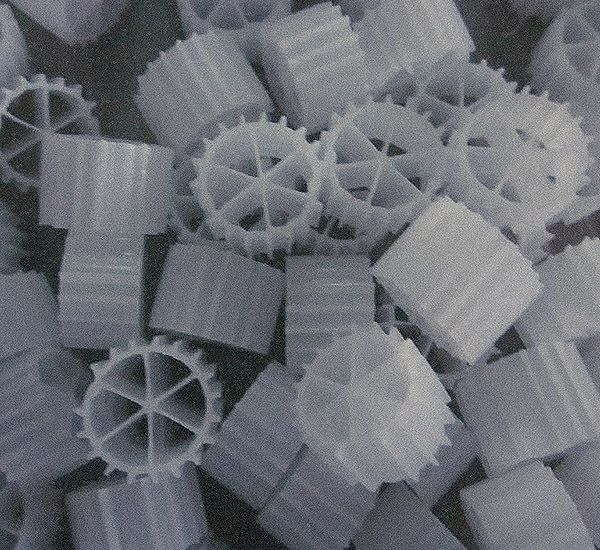

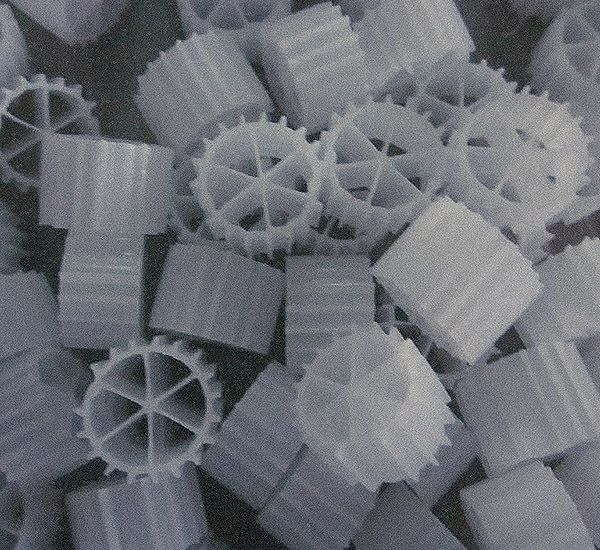

| Biochemical treatment The biochemical treatment stage adopts the advanced and mature MBBR biological treatment process, and the anaerobic filter-aerobic moving-bed organism (A/O+MBBR) process. Principle 1. A/O and aerobic process section has a certain organic matter removal function, replacing the organic load of the subsequent aerobic tank, in order to facilitate the nitrification, and still can achieve denitrification by the higher concentration of organic matter present in the sewage, Eliminate eutrophication of nitrogen. 2. Biochemical process section, using MBBR biological treatment technology, by adding suspended active bio-filler in the biochemical pool, greatly increasing the microbial biomass and microbial population in the reactor, reducing the reactor footprint, while making each of the sewage The pollutants are thoroughly degraded and removed, which guarantees the stable discharge of the effluent. |

|

|

Products & Services

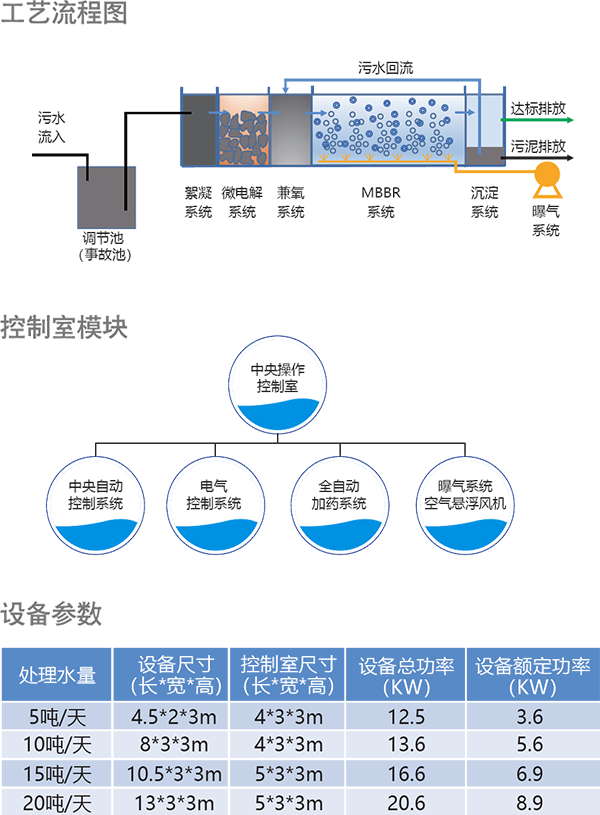

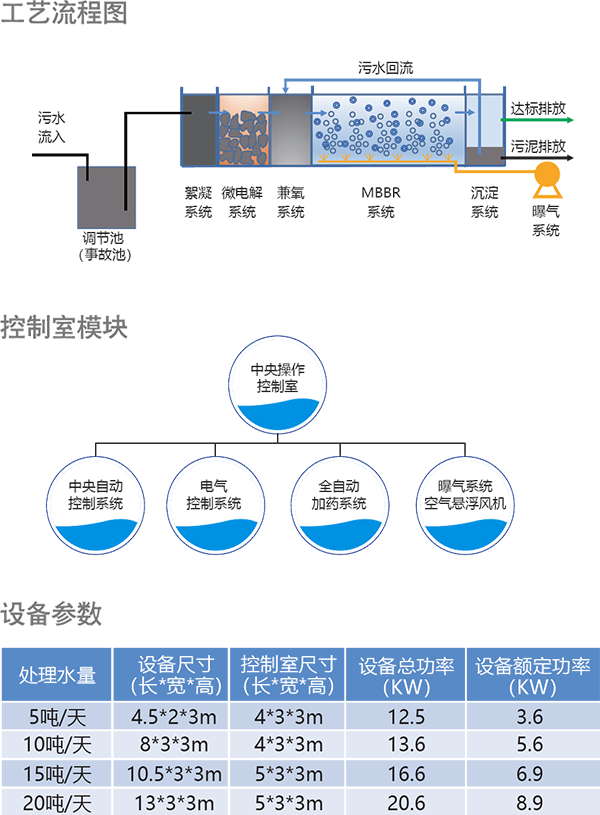

| Integrated Treatment Equipment (5-20 tons / day) Equipment modules: 1. Flocculation system 2. Fe/C micro-electrolytic material treatment system 3. Oxygen system 4. MBBR biochemical treatment system 5. Sedimentation tank system Advantages: 1. Integrated design, small footprint, simple construction, saving investment; low energy consumption, no concentrated liquid or biogas. 2. It can realize continuous operation, stable operation, and can quickly regain vitality under the action of overload or poisoning, so that the treatment effect is stable and the running cost is low. 3. With automatic control, the central control system is easy to operate and easy to manage and maintain; the automatic dosing system can achieve unattended operation and greatly reduce labor costs. 4. Physicochemical treatment process: Using advanced Fe/C micro-electrolysis process, the micro-electrolytic material filled in the waste water is used to generate electrolysis treatment of the wastewater in the absence of electricity, so as to achieve the purpose of degrading organic pollutants. No external power supply is required, and the operation cost is low and safe. 5. Biochemical treatment process: Using advanced MBBR treatment process, the organic matter load can be as high as 6-10kgCOD/m3·d, the removal rate of ammonia nitrogen can reach over 90%, and the nitrogen and phosphorus removal capacity is remarkable. The material of the filler is stable, wear-resistant and durable, and can be used for more than 20 years without replacement, and the system has a long service life. 6. The active bio-filler is added once, no need to add it twice; the suspended active bio-filler is added inside the equipment, high treatment efficiency, stable operation, and good effluent water quality. . |

|

|

Products & Services

| Modular Treatment Equipment (30-100 tons / day) Equipment modules: 1. Air floatation system 2. Flocculation system 3. Sedimentation tank system 4. Oxygen system 5. MBBR biochemical treatment system 6. Fe/C micro-electrolytic material treatment system Advantages: 1. Integrated design, small footprint, simple construction, saving investment; low energy consumption, no concentrated liquid or biogas. 2. It can realize continuous operation, stable operation, and can quickly regain vitality under the action of overload or poisoning, so that the treatment effect is stable and the running cost is low. 3. With automatic control, the central control system is easy to operate and easy to manage and maintain; the automatic dosing system can achieve unattended operation and greatly reduce labor costs. 4. Physicochemical treatment process: Using advanced Fe/C micro-electrolysis process, the micro-electrolytic material filled in the waste water is used to generate electrolysis treatment of the wastewater in the absence of electricity, so as to achieve the purpose of degrading organic pollutants. No external power supply is required, and the operation cost is low and safe. 5. Biochemical treatment process: Using advanced MBBR treatment process, the organic matter load can be as high as 6-10kgCOD/m3·d, the removal rate of ammonia nitrogen can reach over 90%, and the nitrogen and phosphorus removal capacity is remarkable. The material of the filler is stable, wear-resistant and durable, and can be used for more than 20 years without replacement, and the system has a long service life. 6. The active bio-filler is added once, no need to add it twice; the suspended active bio-filler is added inside the equipment, high treatment efficiency, stable operation, and good effluent water quality. . |

|

|