Municipal

Municipal engineering means the construction of all kinds of public infrastructure in cities, including sewage pumping stations, landfills, tunnels etc. These facilities, while providing conveniences to people, are unavoidable to produce a serious of environment pollution, such as smelly gases (such as H₂S) and high concentration corrosive gases (such as SO₂).

IIECC's solution to these problems is to introduce dry-type washing tower of high concentration, which can effectively remove pollutants like toxic and harmful gases to an undetectable level. It is worth mentioning that this solution has low maintenance each year instead of traditional wet-type washers, which maintenance procedure is more complicated and frequent.

Sewage & Waste Water Treatment |

Waste Transfer Station |

Power Generation |

Transportation |

| The stench emitted by pumping stations and sewage treatment containers not only affects and damages People's Daily lives, but also has serious consequences for human health. Each factory has the responsibility to control the smell to avoid affecting nearby residents. Odor in wastewater systems is primarily caused by hydrogen sulfide (H₂S), which is released in the form of a gas. High levels of H2S can lead to odor complaints from the surrounding community and unsafe conditions for workers. In addition, hydrogen sulfide accelerates corrosion in collection systems and wastewater plants, leading to dangerous leaks and costly repairs. |

|

|

|

|

According to specific conditions and equipment installation requirements. IIECC will effectively deal with gas emissions and odor, ensure the environmental compliance of facilities, and create a better life for the surrounding residents. |

|

Products & Services

-

Corrosion Control Series

Engineered to remove acid gases from the polluted gas stream. It provides longer life for industry equipments and machineries through filtering out the corrosive contaminants in airstream.

-

Deodorization Series

Filtering by adsorption or oxidation process to remove the foul smell in air stream.

-

Pressurization Purification System

Pressurization Purification System (PPS) can be used for high concentrations of odors & corrosive contaminants and municipal & industrial air purification and it can also be used for the abatement of releases of toxic airborne contaminants, thus preventin

-

Discharge Filtration System

Discharge Filtration System (DFS) removes corrosive, malodorous and toxic contaminants and is designed for applications requiring high removal efficiency and extensive media life.

-

Corrosion Monitoring

Corrosion monitoring is an accurate and reliable method of evaluating air quality in a controlled environment. Corrosion analysis in the laboratory can provide data on the type and magnitude of gas contamination present in the environment, thereby customi

-

Media Life Analysis

IIECC's Media Life Analysis Service predicts the remaining life of the Filtration Media and provides an accurate maintenance plan to ensure high performance operation of the gas-phase filtration equipment.

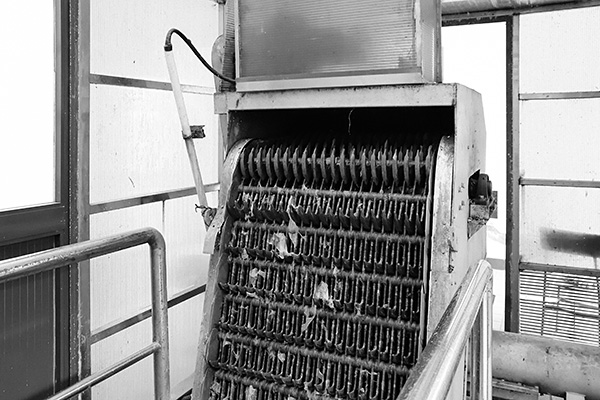

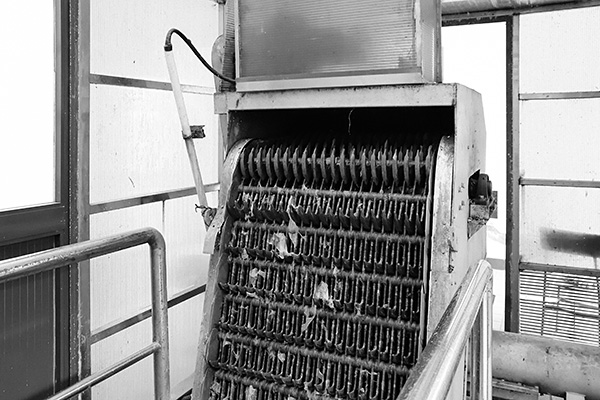

| The odorous molecules generated in the garbage collection and transportation process have the characteristics of large volatility, low boiling point and large odor characterization. The odors produced by various reasons will seriously pollute the environment and deteriorate the quality of the surrounding and surrounding environment. The main types of pollutants controlled by the national standard are hydrogen sulfide, ammonia and odor concentrations. |

|

|

|

|

A complete set of waste control system of odor control system solutions should solve the main contradiction that does not affect the surrounding environment, and at the same time improve the working environment inside the transfer station as much as possible to achieve the improvement of the overall odor control standard. The scheme should mainly consist of a variety of mechanisms: space containment, negative pressure collection and treatment, fresh air circulation supplementation and odor source control. IIECC will effectively deal with gas emissions and odor, ensure the environmental compliance of facilities, and create a better life for the surrounding residents. |

|

Products & Services

-

Discharge Filtration System

Discharge Filtration System (DFS) removes corrosive, malodorous and toxic contaminants and is designed for applications requiring high removal efficiency and extensive media life.

-

Ventilation Filtration Systems

Ventilation Filtration System (VFS) is a type of air filtration equipment that designed for meeting the needs of indoor air ventilation and purification. It is filled with IIECC Filtration Media to purify the air from outdoor to protect people from air po

| In the current process industry operation, the dependence on distributed control systems, instrumentation and electronic information systems with electronic components as the core is becoming stronger and stronger. The stable and safe operation of these automation platforms and equipment has become a key link to ensure the normal operation of the entire production process in the power industry. Switch cabinets and electronic devices are particularly susceptible to faults when they are exposed to aggressive and damp ambient air. Many applications result in the production of acidic gases that can attack and damage process-critical components in control rooms. Avoid downtimes and cost-intensive maintenance with reliable corrosion protection. |

|

|

|

|

With IIECC filtration solutions, corrosive contaminant gases can be effectively removed from the process air. Gas phase filtration reliably protects your devices against corrosion and its consequences; this protects your systems and ensures fault-free operation. |

|

Products & Services

-

Indoor Air Quality Series

Engineered to purify a wide variety of odorous and contaminates from indoor air.

-

Targeted Contaminants Removal Series

Filtering by adsorption or oxidation process and engineered to provide superior performance in removing selected contaminants.

-

Corrosion Control Series

Engineered to remove acid gases from the polluted gas stream. It provides longer life for industry equipments and machineries through filtering out the corrosive contaminants in airstream.

-

Pressurization Purification System

Pressurization Purification System (PPS) can be used for high concentrations of odors & corrosive contaminants and municipal & industrial air purification and it can also be used for the abatement of releases of toxic airborne contaminants, thus preventin

-

Recirculation Purification System

Recirculation Purification System (RPS) is an independent and complete air purification equipment. It is designed to be placed indoors, and the air is circulated and purified to protect people from indoor air pollution, and make sure that the electronic

-

MAHS Series

MAHS offers total design flexibility for the control of particulate contaminants as well as gaseous contaminants.

| Motor engines emit a range of pollutants which may be harmful to human health and the environment, including carbon monoxide (CO), nitrogen oxides (NOx), particulate matter, hydrocarbons and lead (in countries where lead is still permitted as an additive to petroleum fuel). Particulate matter that is 10μm or less in diameter is also generated by the wear on rubber tyres and brake pads. The physiological and environmental effects of vehicular emissions are reasonably well known. Due to employment of catalytic converters in petrol engines, and the shift to diesel engines, carbon monoxide emissions have been falling significantly in recent years, to the extent that this particular pollutant is no longer considered a critical determinant of roadside air quality. |

|

|

|

|

Instead, nitrogen oxides and particulate matter are now of greatest concern to policy makers and designers. Nitrogen dioxide (NO₂) affects the human respiratory response, especially for asthmatic individuals, whose response to allergens can be negatively enhanced. NO₂ is produced as a direct result of engine combustion, and also as a product of the oxidization of nitric oxide (NO) in the presence of ozone(O₃) and sunlight. Tunnels do not generate emissions – rather, they confine and redistribute emissions given off by vehicles passing through them. Instead of being emitted into the outside environment along the road length, airborne pollutants are discharged at tunnel portals, or through ventilation stacks. |

|

|

| Tunnel ventilation systems must be able to provide adequate air quality during normal operation in addition to supporting self-evacuation and rescue efforts during emergency incidents. Carbon monoxide CO is traditionally taken as the reference emission for the assessment of the toxicity of exhaust gases. The concentration of diesel-smoke as well as of non-exhaust particle emissions is the reference for visibility in the tunnel. In some countries, nitrogen dioxide NO₂ is also taken into account regarding the in-tunnel air quality. For environmental reasons, the ambient air quality at the tunnel portals often has to adhere to certain thresholds of NO₂. Consequently, the requirements for in-tunnel air quality or ambient air quality at the tunnel portals may determine the capacity requirements of the ventilation system. |

|

|

|

|

In addition, the air quality in the subway metro indoor microenvironment has been of particular public concern. Subway metro systems have been rapidly developed worldwide in last decades. The number of metro commuters has continuously increased over recent years in metropolitan cities. In some cities, metro system has become the primary public transportation mode. Although commuters typically spend only 30–40 min in metros, the air pollutants emitted from various interior components of metro system as well as air pollutants carried by ventilation supply air are significant sources of harmful air pollutants that could lead to unhealthy human exposure. |

|

|

| Particulate matters, aromatic hydrocarbons, carbonyls and airborne bacteria have been identified as the primary air pollutants inside metro system. Commuters' exposure to various air pollutants in metro carriages may cause perceivable health risk as reported by many environmental health studies. IIECC's solution aimed to improve the amenity of users by improving air quality |

|

|